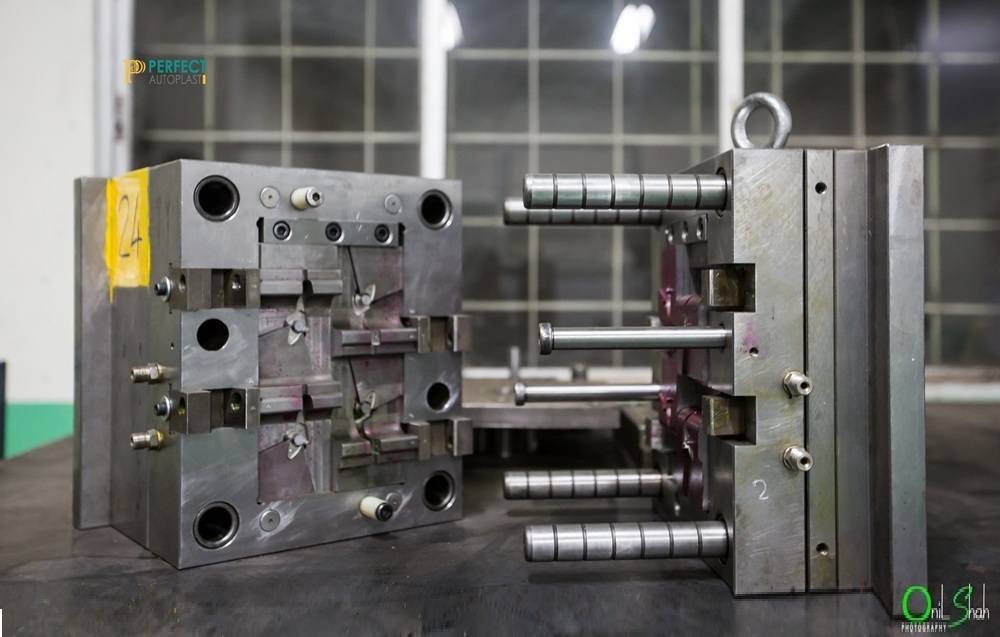

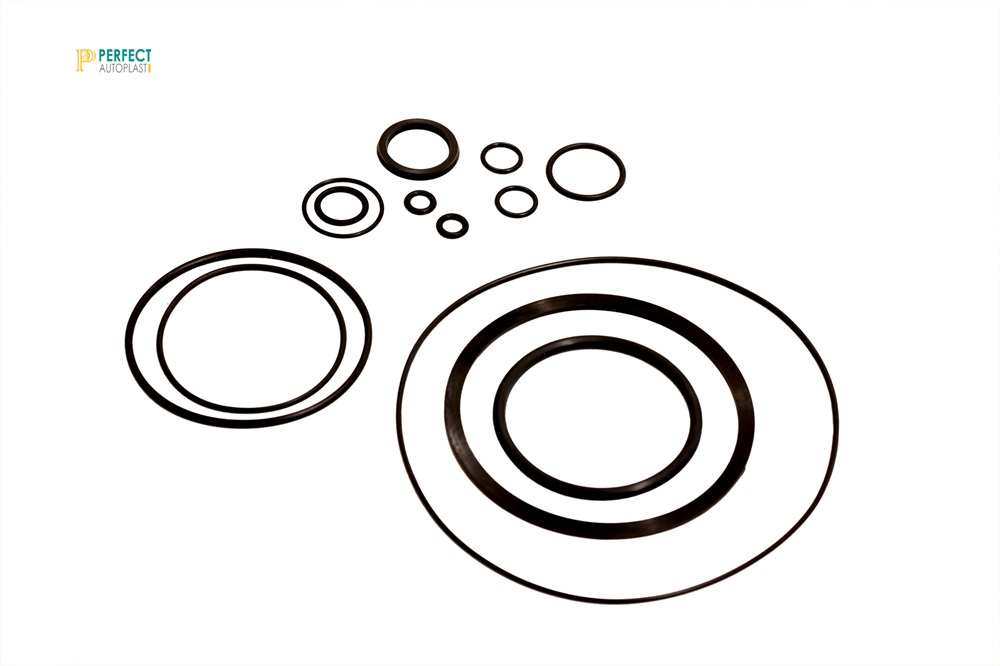

Die making is a cornerstone of high-precision manufacturing at Perfect Auto Plast. Our expert team specializes in the design, development, and fabrication of high-accuracy moulds and dies for compression rubber moulds. With advanced CAD/CAM software and modern CNC (Computer Numerical Control) machining,EDM (Electric Discharge Machine) capabilities, VMC machine (Vertical Machining Center) we ensure that every die is manufactured to exact tolerances.

In-house tooling unit is equipped with CNC milling machines, EDM (Electrical Discharge Machining), surface grinding, and other high-precision equipment. From single-cavity to multi-cavity dies, we support a wide range of complexities and part geometries while ensuring long tool life and repeatability.

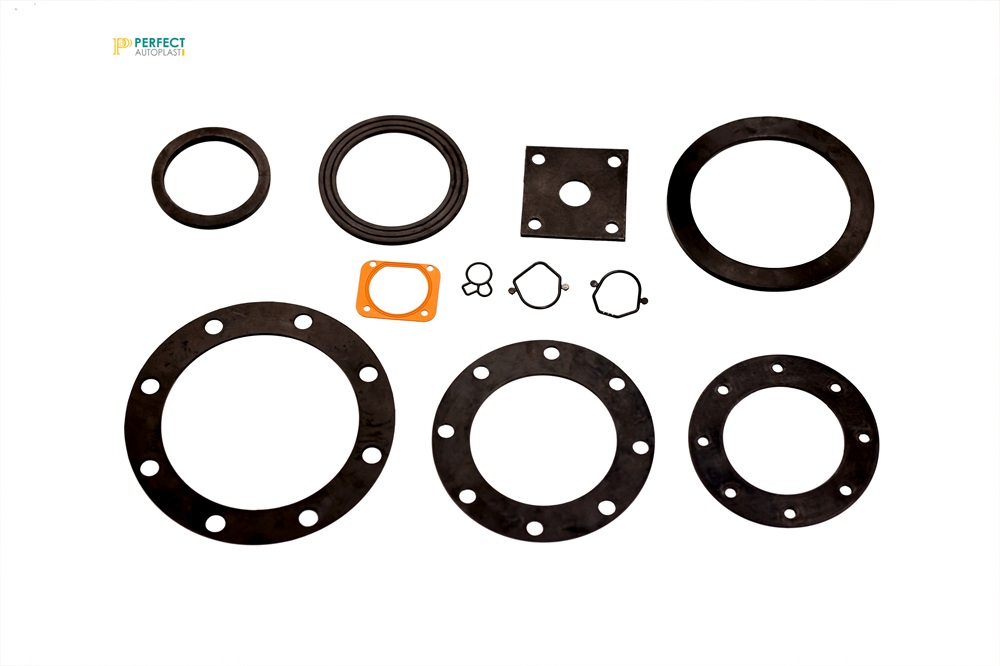

We follow a detailed validation process including first article inspection, mold trials, and pilot production runs. This ensures that the dies function flawlessly under real production conditions and produce consistent, defect-free parts.

From design to delivery, Die-making process focuses on precision, efficiency, and durability—ensuring a perfect fit for your production requirements.

At Perfect Auto Plast, we understand that the quality of your die determines the quality of your final product. Die making services ensure dimensional accuracy, repeatability, and durability with fast turnaround times. Whether for prototypes or production-grade tools, we deliver excellence with every die we make.