Quality at Perfect Auto Plast

At Perfect Auto Plast, quality isn’t just a process — it’s our promise. Every component we manufacture is a reflection of precision, reliability, and our unwavering commitment to excellence.

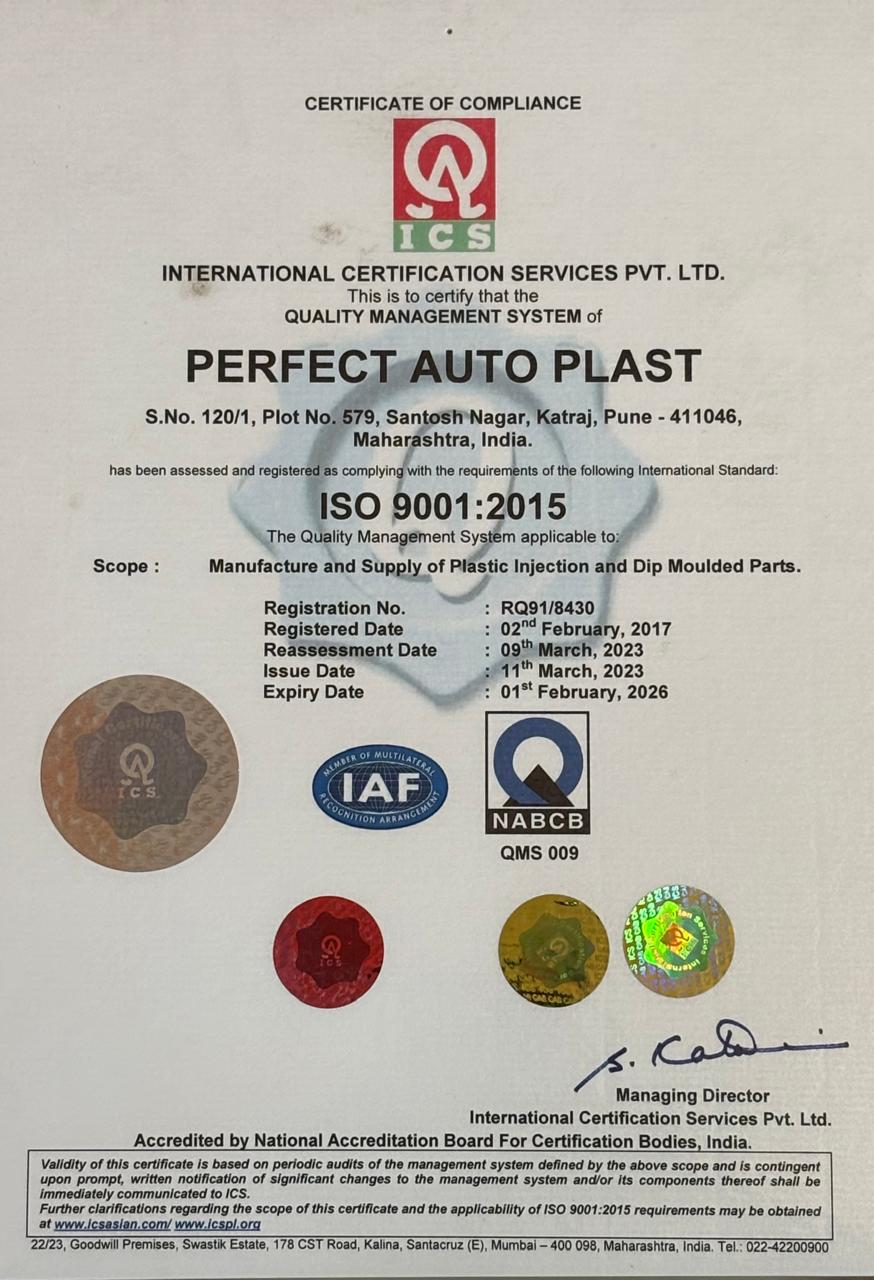

We are an ISO 9001:2015 certified company, operating under a robust quality management system that ensures consistency, traceability, and continuous improvement across all our operations.

We back our precision engineering with a full suite of high-accuracy instruments including vernier calipers, micrometers, bore gauges, and custom-designed testing jigs tailored to customer-specific requirements. Our Video Measuring Machine (VMM) is a high-precision system from CARMAR — a leading metrology brand from Taiwan known for accuracy and reliability. It enables non-contact, micron-level inspection of complex and critical dimensions. With this advanced capability, we ensure consistent precision across batches, especially for intricate parts and tight tolerances.

Currently, we are successfully manufacturing plastic parts with tolerances as close as 20 microns, showcasing our ability to meet the most demanding dimensional requirements with absolute consistency, We also provide third-party raw material testing reports as required by the customer or on an annual basis, ensuring transparency and material traceability at every step.

Each and every part that leaves our facility undergoes 100% visual inspection by our trained quality team, strictly following the defined Quality Control Plan. No part moves forward until it meets desired standards.

For parts that demand unique testing conditions, we go a step further Using specialized testing machines in-house to meet exact customer specs.

At Perfect Auto Plast, we don’t just meet quality expectations — we engineer confidence into every component we deliver.Perfect Auto Plast